Quality control takes a special place in the technology of the FARA system, as the high quality of the result is the key to the commercial success of the whole project.

The technology provides for a two-stage quality control system - daily monitoring during field work and final control when processing the data.

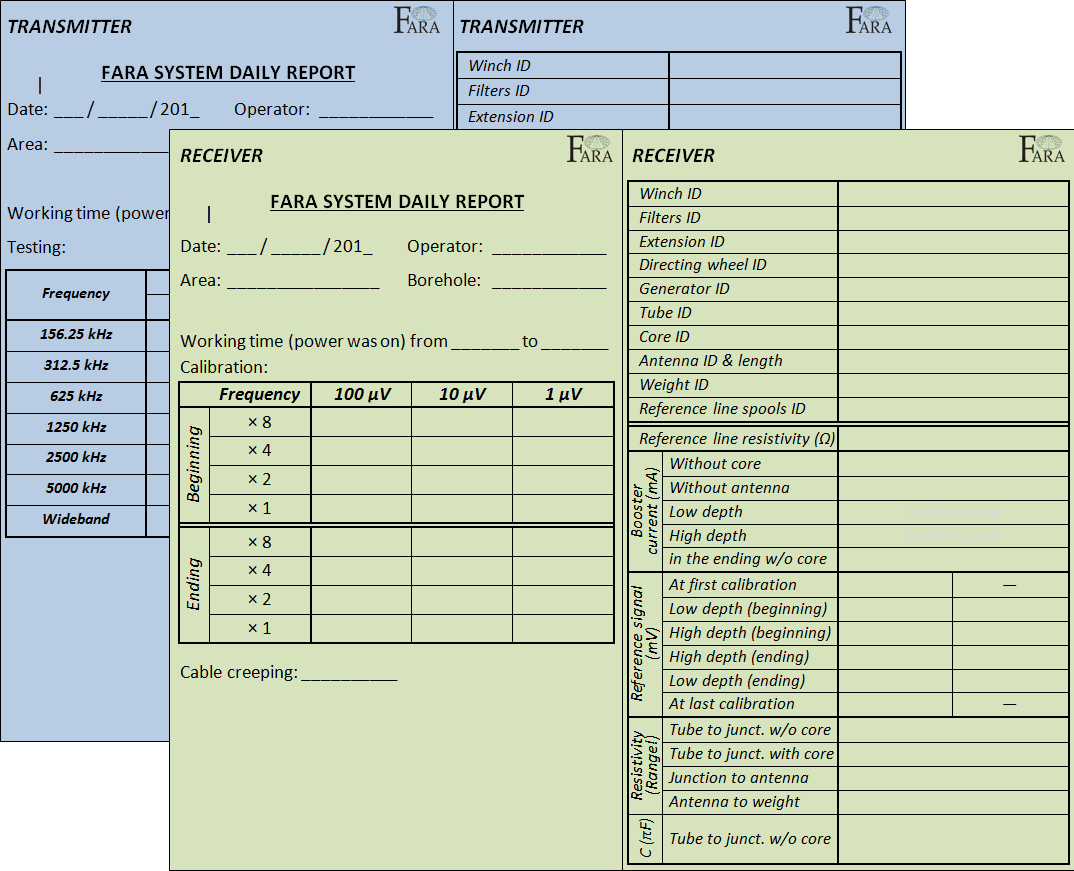

Daily technical report

When working with the FARA system, a number of tests are performed, which make it possible to verify the

operability of the equipment.

Tests are conducted daily before the start of measurements, and also after their completion.

Among other things, the components of downhole systems are tested. A check is made not only of electrical

resistance, but also of electrical capacity, which helps to determine the places of potential leaks.

The receiver system is tested using the emulator of the transmitter system, the transmitter system - using the

emulator of the receiver system.

The test results are recorded in special forms of the daily technical report. As a result, information accumulates,

which helps to monitor the history of the equipment condition, predict the occurrence of malfunctions and

prescribe preventive maintenance.

Quality control in data processing

Usually measurements with the FARA system are carried out from two sides. In fact, measurements are carried out twice - for the first time the transmitter is located in borehole 1, the

receiver - in borehole 2; the second time they change places - the transmitter in the borehole 2, and the receiver in the borehole 1. As a result, two independent sets of primary data are

obtained, which can be processed both together or separately.

Comparison of tomographic images from data obtained from different sides is a reliable criterion of the overall quality of the obtained result .

The image shows two tomographic images from data obtained from different sides, as well as the result of combined processing. It is clear that the images from different sides have

good correlation, the main anomalies have the same location and shape, which is an irrefutable evidence of the high quality of the data received and, accordingly, the reliability of the

result.

Combined processing of data from both sides allows to obtain the final result, which is characterized by uniform reliability over the whole plane of the section, including cincluding the

space near the boreholes.